Printed Circuit Boards (PCBs) are the unsung heroes of the automation revolution, powering everything from massive industrial robots to tiny smart home devices. As automation continues to transform industries and daily life, the importance of PCBs in enabling these advancements cannot be overstated. This article explores the crucial role that PCBs play in the automation industry, from large-scale manufacturing to consumer-grade robotics.

Device Examples in Industrial Automation

PCBs are at the heart of numerous automation devices and systems, including:

- Programmable Logic Controllers (PLCs): These industrial computer control systems rely on PCBs to manage complex automated processes in manufacturing plants.

- Industrial Robots: From welding robots in automotive plants to pick-and-place machines in electronics assembly, PCBs control the precise movements and functions of these automated workers.

- Automated Guided Vehicles (AGVs): PCBs enable the navigation, obstacle detection, and task management of these self-driving vehicles used in warehouses and factories.

- Machine Vision Systems: PCB-based cameras and image processing units allow automated quality control and object recognition in production lines.

- Smart Sensors: IoT-enabled sensors with integrated PCBs monitor equipment health, environmental conditions, and process parameters in real-time.

Printed Circuit Boards (PCBs) are the unsung heroes of the automation revolution, powering everything from massive industrial robots to tiny smart home devices. As automation continues to transform industries and daily life, the importance of PCBs in enabling these advancements cannot be overstated. This article explores the crucial role that PCBs play in the automation industry, from large-scale manufacturing to consumer-grade robotics.

Device Examples in Industrial Automation

PCBs are at the heart of numerous automation devices and systems, including:

- Programmable Logic Controllers (PLCs): These industrial computer control systems rely on PCBs to manage complex automated processes in manufacturing plants.

- Industrial Robots: From welding robots in automotive plants to pick-and-place machines in electronics assembly, PCBs control the precise movements and functions of these automated workers.

- Automated Guided Vehicles (AGVs): PCBs enable the navigation, obstacle detection, and task management of these self-driving vehicles used in warehouses and factories.

- Machine Vision Systems: PCB-based cameras and image processing units allow automated quality control and object recognition in production lines.

- Smart Sensors: IoT-enabled sensors with integrated PCBs monitor equipment health, environmental conditions, and process parameters in real-time.

Consumer Automation and Robotics

The influence of PCBs extends beyond industrial applications into our homes and daily lives:

1. Robot Vacuums: These popular household helpers use PCBs to control navigation, suction power, and scheduling.

2. Smart Thermostats: PCBs enable these devices to learn user preferences, optimize energy usage, and integrate with home automation systems.

3. Drone Technology: From recreational drones to delivery drones, PCBs control flight stabilization, navigation, and communication systems.

4. Automated Pet Feeders: PCBs manage portion control, scheduling, and even video monitoring in these convenient devices.

5. Smart Appliances: Refrigerators, washing machines, and ovens increasingly incorporate PCB-based control systems for enhanced functionality and energy efficiency.

Electronics PCB Assembly for Automation

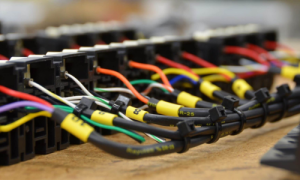

The assembly process for automation-focused printed circuit boards requires precision and reliability:

- Component Selection: Automation devices often require high-performance microcontrollers, precise sensors, and robust power management components.

- Surface Mount Technology (SMT): Most automation PCBs use SMT for compact designs and improved reliability in high-vibration environments.

- Automated Assembly: Ironically, the PCBs that power automation are themselves often assembled by automated pick-and-place machines and reflow ovens.

- Quality Control: Automated optical inspection (AOI) and X-ray inspection ensure the quality of solder joints and component placement.

- Conformal Coating: Many automation PCBs receive a protective coating to guard against moisture, dust, and chemicals in industrial environments.

Electronics PCB Assembly for Automation

The assembly process for automation-focused printed circuit boards requires precision and reliability:

- Component Selection: Automation devices often require high-performance microcontrollers, precise sensors, and robust power management components.

- Surface Mount Technology (SMT): Most automation PCBs use SMT for compact designs and improved reliability in high-vibration environments.

- Automated Assembly: Ironically, the PCBs that power automation are themselves often assembled by automated pick-and-place machines and reflow ovens.

- Quality Control: Automated optical inspection (AOI) and X-ray inspection ensure the quality of solder joints and component placement.

- Conformal Coating: Many automation PCBs receive a protective coating to guard against moisture, dust, and chemicals in industrial environments.

PCB Design Tips for Automation-Related Products

Designing PCBs for automation applications requires special considerations:

- EMI/RFI Shielding: Proper layout techniques and shielding are crucial to prevent electromagnetic interference in noisy industrial environments.

- Thermal Management: Many automation devices operate continuously, requiring careful thermal design to dissipate heat effectively.

- Modular Design: Creating modular PCB designs can simplify maintenance and upgrades in industrial automation systems.

- Ruggedization: PCBs for industrial automation often need to withstand extreme temperatures, vibrations, and harsh chemicals.

- Safety Features: Incorporating fail-safes and redundancies is crucial for PCBs controlling critical automated processes.

- Connectivity: Many modern automation devices require wireless connectivity (Wi-Fi, Bluetooth, or cellular) for remote monitoring and control.

PCBs for Automated Assembly Processing Machines

In a fascinating twist, PCBs are also crucial components in the machines that assemble other PCBs:

- Pick-and-Place Machines: PCBs control the precise movements of component placement heads, ensuring accurate and rapid assembly.

- Reflow Ovens: PCB-based control systems manage temperature profiles and conveyor speeds for optimal soldering results.

- Wave Soldering Machines: PCBs regulate solder wave height, conveyor speed, and preheat temperatures in these through-hole assembly machines.

- Automated Optical Inspection (AOI) Systems: Sophisticated PCBs process image data to detect defects in assembled circuit boards.

- Component Feeders: PCB-controlled feeders ensure a steady supply of components to pick-and-place machines.

PCBs for Automated Assembly Processing Machines

In a fascinating twist, PCBs are also crucial components in the machines that assemble other PCBs:

- Pick-and-Place Machines: PCBs control the precise movements of component placement heads, ensuring accurate and rapid assembly.

- Reflow Ovens: PCB-based control systems manage temperature profiles and conveyor speeds for optimal soldering results.

- Wave Soldering Machines: PCBs regulate solder wave height, conveyor speed, and preheat temperatures in these through-hole assembly machines.

- Automated Optical Inspection (AOI) Systems: Sophisticated PCBs process image data to detect defects in assembled circuit boards.

- Component Feeders: PCB-controlled feeders ensure a steady supply of components to pick-and-place machines.

Prototyping and Testing PCB Components for Automation

Rigorous prototyping and testing are essential for automation-focused PCBs:

- Rapid Prototyping: Advanced PCB fabrication techniques allow for quick iterations of prototype designs.

- In-Circuit Testing (ICT): Automated test equipment verifies the correct assembly and functionality of PCBs before they’re integrated into automation devices.

- Environmental Testing: PCBs undergo temperature cycling, vibration testing, and humidity exposure to simulate real-world conditions.

- EMC Testing: Electromagnetic compatibility testing ensures that PCBs won’t interfere with other equipment or be susceptible to external interference.

- Reliability Testing: Accelerated life testing helps predict the long-term performance of PCBs in automation applications.

- Functional Testing: PCBs are tested in simulated automation scenarios to verify their performance under expected operating conditions.

The Future of PCBs in Automation

- As automation continues to advance, PCB technology is evolving to meet new challenges:

- Increased Miniaturization: Smaller, more densely packed PCBs will enable further miniaturization of automation devices.

- Flexible and 3D PCBs: Non-traditional PCB forms will allow for more creative and efficient designs in robotics and automation.

- Integration of AI: PCBs will increasingly incorporate AI processors for edge computing in automated systems.

- Enhanced Durability: New materials and manufacturing techniques will produce PCBs capable of withstanding even harsher industrial environments.

- Green Manufacturing: PCB design and production will focus on sustainability, with increased use of recyclable materials and energy-efficient processes.

Conclusions

The role of printed circuit boards in the automation industry cannot be overstated. From the factory floor to our living rooms, PCBs are the silent enablers of the automated systems that are reshaping our world. As automation technology continues to evolve, so too will the PCBs that power new, innovative products and manufacturing processes.

For engineers and businesses involved in automation, staying abreast of PCB technology trends is crucial. The ability to design and implement cutting-edge PCBs will be a key differentiator in developing the next generation of automated systems and robotic devices.

As we look to the future, we can expect PCBs to become even more integral to automation. They will continue to shrink in size, grow in capability, and expand their reach into new applications. From small toy robots to city-wide smart infrastructure, PCBs will be there, quietly orchestrating the automated world of tomorrow.

The next time you interact with an automated system – whether it’s a robotic arm in a factory or a smart speaker in your home – remember the intricate printed circuit boards working behind the scenes. These marvels of electronic engineering are the true workhorses of the automation revolution, turning the dreams of science fiction into the realities of our automated present and future.

Trust BENCOR as your full-service industrial contract manufacturer to manage every stage of the PCB manufacturing process, from initial design and prototyping to final assembled products validated and ready for seamless deployment into your automated product ecosystem.