In the precise world of electronics manufacturing, consistency and quality are not abstract concepts—they are measurable standards that define a product’s reliability. To ensure that a Printed Circuit Board (PCB) assembled in one facility meets the same quality criteria as one assembled a thousand miles away, the industry relies on a set of globally recognized standards. The leading authority for these standards is IPC (the Association Connecting Electronics Industries), and their IPC-A-610, “Acceptability of Electronic Assemblies,” is the definitive rulebook used worldwide to define what constitutes a quality solder joint, a correctly placed component, and a reliable assembly. Within this critical standard, IPC defines three “Classes” of electronic products. While Class 1 covers general consumer electronics, the most relevant standards for professional products are Class 2 and Class 3. Understanding the differences between these two is not just an academic exercise; it’s a critical strategic decision that impacts a product’s performance, lifespan, and cost. As a proud American manufacturer committed to excellence, BENCOR is fluent in the language of IPC standards and is equipped to build to the precise level of quality your product demands.

What are the IPC Performance Classes? A Framework for Reliability

t’s a common misconception to think of the IPC classes as “bad, good, and best.” A more accurate way to view them is a framework for matching the level of manufacturing quality and rigor to the product’s intended end-use environment. The classes are designed to ensure a product is appropriately reliable for its specific mission, balancing performance requirements with manufacturing cost.

Class 1 – General Electronic Products

This class covers products where the primary requirement is simply the function of the completed assembly. It allows for a wider range of cosmetic imperfections. Think of everyday consumer electronics, simple toys, or products with a limited life expectancy where the cost of manufacturing is the primary driver.

Class 2 – Dedicated Service Electronic Products

This is the default standard for the vast majority of professional and high-performance commercial electronic products. Class 2 is defined for products where continued performance and an extended service life are required. While uninterrupted service is desired, it is not critical, meaning a failure would not typically cause a life-threatening or mission-critical situation. Think of laptops, servers, smartphones, televisions, and general industrial controls. The expectation is high performance and a long, reliable life.

Class 3 – High-Performance/Harsh-Environment Electronic Products

Class 3 represents the highest standard of manufacturing quality and is reserved for the most demanding applications. It covers products where continued high performance or “performance-on-demand” is absolutely critical. In these applications, equipment downtime cannot be tolerated, the end-use environment may be uncommonly harsh, and a product failure could have catastrophic consequences. Think of life-support medical devices like pacemakers and defibrillators, aerospace flight control systems, military hardware, and critical downhole tools for the oil and gas industry.

Key Differences in Manufacturing and Acceptance Criteria

The shift from Class 2 to Class 3 is defined by a significant tightening of the manufacturing tolerances and acceptance criteria. While a Class 2 assembly is robust and reliable, a Class 3 assembly is built with an extra layer of rigor designed to minimize any potential sources of failure over the product’s life, especially when subjected to harsh conditions. Here are some of the key differences:

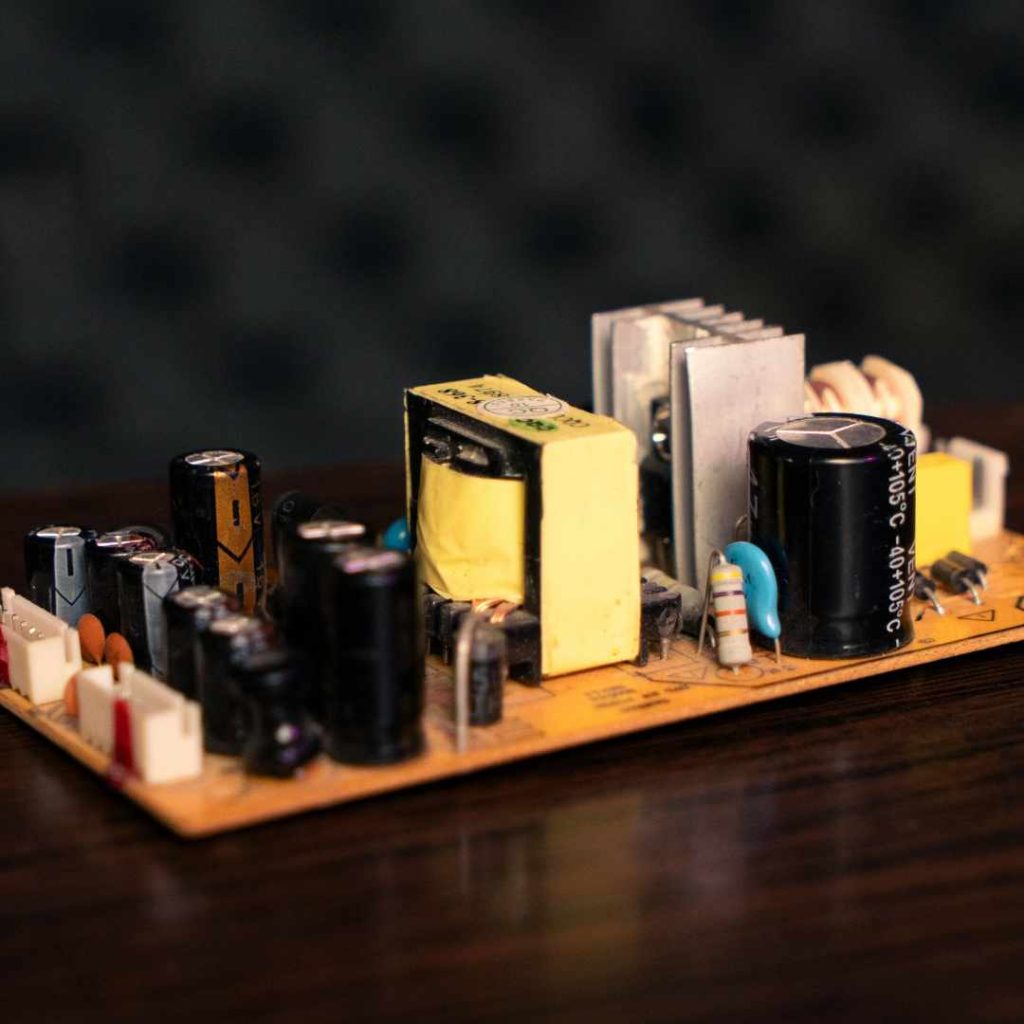

Through-Hole Soldering (Barrel Fill)

For components with leads that go through holes in the board (Plated-Through Hole or PTH), the amount of solder that wicks up into the hole (the “barrel”) is a key indicator of joint strength.

Class 2: Requires a minimum of 75% vertical solder fill in the barrel.

Class 3: Also requires 75% vertical fill but adds stricter criteria for the solder fillets on the component and solder sides of the board. There is less tolerance for conditions like exposed copper at the edge of the hole, ensuring a more robust mechanical and electrical connection that is less susceptible to failure from vibration or thermal stress.

How a component sits on its pads has a direct impact on the quality of the solder joints.

Class 2: Allows for some minor component overhang. For example, a small chip resistor’s termination can hang off the side of its pad by up to 50%, as long as a reliable solder joint is still formed.

Class 3: Has much tighter placement requirements. For that same chip resistor, absolutely no side overhang is permitted. The component termination must be fully on the pad. This ensures the maximum possible solderable area is utilized, creating the strongest possible joint.

Component Placement Tolerances

Component Placement Tolerances

How a component sits on its pads has a direct impact on the quality of the solder joints.

Class 2: Allows for some minor component overhang. For example, a small chip resistor’s termination can hang off the side of its pad by up to 50%, as long as a reliable solder joint is still formed.

Class 3: Has much tighter placement requirements. For that same chip resistor, absolutely no side overhang is permitted. The component termination must be fully on the pad. This ensures the maximum possible solderable area is utilized, creating the strongest possible joint.

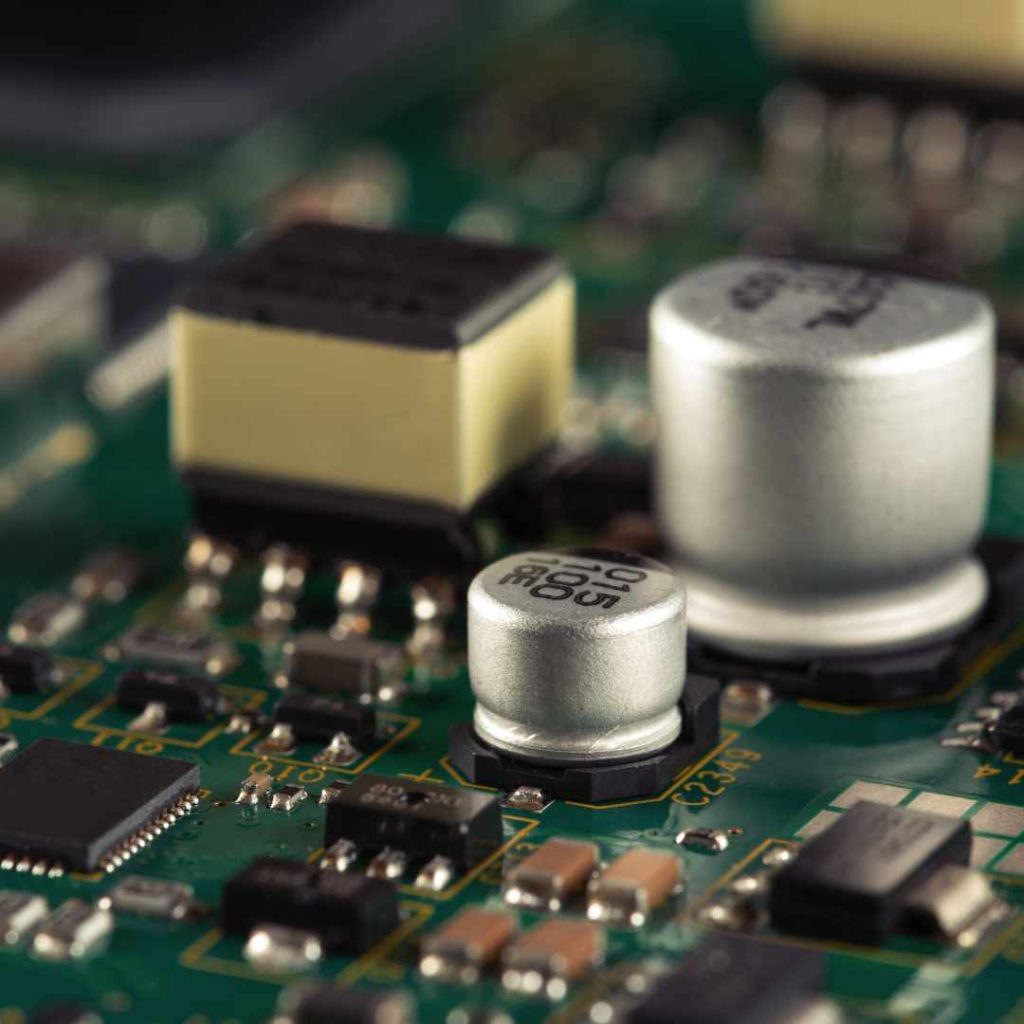

SMT Solder Joint Criteria

The specific requirements for the size and shape of the solder fillet on surface-mount components are more stringent for Class 3. For example, for “gull-wing” leads found on many integrated circuits, Class 3 may require a greater minimum solder height up the side of the lead (the “heel fillet”), ensuring a more durable connection.

After soldering, flux residues can be left on the board. While modern “no-clean” fluxes are designed to be benign, in high-reliability or high-voltage applications, these residues can still pose a risk of electrochemical migration over time. While both classes require boards to be free of harmful contaminants, Class 3 often mandates a more stringent level of cleanliness, sometimes requiring a full wash process even when no-clean flux is used, to ensure the highest level of long-term reliability.

PCB Cleanliness

PCB Cleanliness

After soldering, flux residues can be left on the board. While modern “no-clean” fluxes are designed to be benign, in high-reliability or high-voltage applications, these residues can still pose a risk of electrochemical migration over time. While both classes require boards to be free of harmful contaminants, Class 3 often mandates a more stringent level of cleanliness, sometimes requiring a full wash process even when no-clean flux is used, to ensure the highest level of long-term reliability.

PCB Fabrication Requirements

While technically part of the PCB fabrication standard (IPC-6012), the acceptability of the bare board is referenced by IPC-A-610. Class 3 imposes stricter requirements on the fabrication itself, such as a greater minimum width for the annular ring (the copper pad surrounding a drilled hole), to ensure vias do not break out from their pads, which could lead to connection failures under stress.

In summary, the transition from Class 2 to Class 3 is a deliberate move from ensuring high performance to guaranteeing high reliability. It’s achieved by tightening tolerances, increasing solder volume requirements where it matters, and minimizing any condition that could potentially become a point of failure in the future.

Which Class Do You Need? A Strategic and Economic Decision

Choosing between Class 2 and Class 3 is a strategic decision that must balance the product’s mission requirements against the cost of manufacturing.

For the vast majority of electronic products manufactured today, Class 2 is the appropriate and most cost-effective standard. It delivers a highly reliable product suitable for long-term service in most commercial, industrial, and consumer applications. If the consequence of a failure is primarily financial (e.g., a warranty replacement) rather than catastrophic, Class 2 provides the perfect balance of quality, performance, and cost.

You should specify Class 3 when the product’s failure could have severe consequences. If the device is part of a life-support system, a flight-critical avionics package, a military weapon system, or any application where performance-on-demand is a matter of safety or mission success, the additional rigor of Class 3 is an absolute necessity.

It is important to be transparent: building to Class 3 standards is more expensive. The stricter tolerances mean that manufacturing processes often need to run slower and require more intensive inspection, including 100% inspection of certain features rather than sample-based checks. It requires more highly trained and certified operators. The initial production yield may be slightly lower because assemblies that would be perfectly acceptable for Class 2 may be rejected under Class 3 rules. This increased cost should not be seen as a penalty but as a direct investment in risk mitigation for your most critical applications.

The BENCOR Commitment: Building to Your Standard of Excellence

At BENCOR, we are fluent in the language of IPC standards. Our quality management systems, certified to ISO 9001:2015, our skilled American workforce, and our advanced process controls give us the capability to consistently and reliably build to both IPC Class 2 and Class 3 requirements.

We view our role as more than just an assembler; we are your manufacturing partner. Our team works with you to understand your product’s application and intended environment. This consultative approach allows us to help you make an informed decision on the appropriate class for your assembly. We ensure you are not over-specifying and overpaying for Class 3 when the robust reliability of Class 2 is perfectly sufficient for your needs. Conversely, when your application demands the uncompromising rigor of Class 3, we have the processes and expertise in place to deliver.

This capability to manufacture to the industry’s highest reliability standard is a hallmark of top-tier American manufacturing. It represents a deep commitment to precision, discipline, and a zero-defect quality mindset that is essential for our nation’s most critical and innovative industries. It is a level of trust and quality that is meticulously built into every solder joint.

Conclusion:

The choice between IPC Class 2 and Class 3 is a critical decision that defines a product’s reliability profile. Class 2 is the standard for high-performance commercial products, while Class 3 provides the high-reliability assurance needed for mission-critical applications where failure is not an option. The right choice depends entirely on your product’s end-use and the consequences of a potential failure. Partnering with a knowledgeable American CEM like BENCOR, who is not only capable of building to these exacting standards but can also guide you in making the right choice, is essential for ensuring your product is not just functional, but perfectly and reliably suited for its mission.