The manufacturing landscape is undergoing a profound transformation, driven by the rapid growth of the Industrial Internet of Things (IIoT). This interconnected network of devices, machines, and sensors is generating vast amounts of data, providing unprecedented insights into operations, and paving the way for smarter, more efficient, and more responsive manufacturing processes. At the heart of this revolution are “smart” Printed Circuit Boards (PCBs) – the foundational building blocks that enable IIoT devices to function.

What is the Industrial Internet of Things (IIoT)?

The IIoT, a subset of the broader Internet of Things (IoT), specifically focuses on industrial applications. Unlike consumer IoT (smartwatches, smart home devices), IIoT deals with the connection of machines, sensors, and control systems in industries like manufacturing, energy, oil and gas, logistics, and transportation. It’s about creating a network where industrial assets can communicate, share data, and trigger actions – often without human intervention. This interconnectedness allows for real-time monitoring, data-driven decision-making, and automation of complex processes.

What is the Industrial Internet of Things (IIoT)?

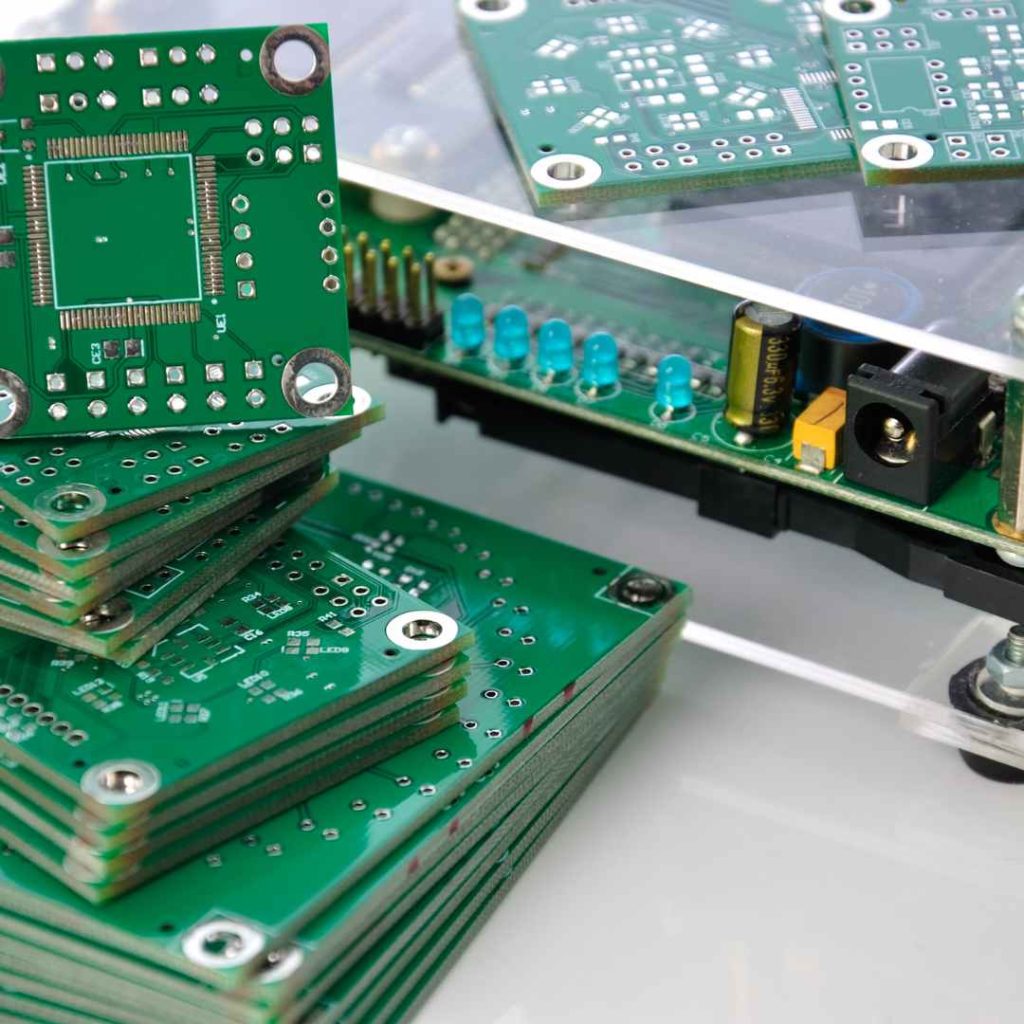

Traditional PCBs are the “nervous system” of electronic devices, providing the pathways for electrical signals. “Smart” PCBs for IIoT go far beyond this basic function. They are designed and manufactured to incorporate:

Embedded Sensors: These sensors measure a wide range of parameters, including temperature, pressure, vibration, humidity, proximity, motion, and chemical composition. This data provides a constant stream of information about the operating environment and the condition of equipment.

Wireless Connectivity: Smart PCBs utilize various wireless communication protocols such as Wi-Fi, Bluetooth, Zigbee, LoRaWAN, and cellular (4G/5G) to transmit data to central systems or other devices. This eliminates the need for costly and complex wiring, enabling greater flexibility and scalability.

Microcontrollers and Processors: These on-board processing units enable the PCB to perform local data analysis, make decisions based on pre-programmed rules, and even execute simple control actions. This “edge computing” capability reduces latency and bandwidth requirements, as not all data needs to be sent to the cloud for processing.

Power Management: Many IIoT devices operate in remote or battery-powered environments. Smart PCBs incorporate power management circuits to optimize energy consumption and extend battery life.

Robust Design: Industrial environments can be harsh, with exposure to extreme temperatures, vibrations, dust, and moisture. Smart PCBs for IIoT are designed to withstand these conditions, ensuring reliability and longevity.

Key Benefits of IIoT and Smart PCBs in Manufacturing

The implementation of IIoT solutions, powered by smart PCBs, offers a wide range of benefits for manufacturers:

Predictive Maintenance: This is perhaps the most significant benefit. By continuously monitoring the condition of equipment through embedded sensors, potential failures can be identified before they occur. This allows maintenance to be scheduled proactively, minimizing downtime, reducing repair costs, and extending the lifespan of valuable assets. For example, a sensor on a motor might detect unusual vibrations, indicating an impending bearing failure. This allows maintenance to be scheduled during a planned downtime, rather than facing an unexpected and costly production halt.

Process Optimization: Real-time data from IIoT devices provides a granular view of production processes. Manufacturers can identify bottlenecks, inefficiencies, and areas for improvement. This data-driven approach leads to increased throughput, reduced waste, and improved resource utilization. For instance, tracking the flow of materials through a factory can reveal areas where delays are occurring, allowing for adjustments to optimize the production line.

Improved Quality Control: Sensors embedded in the production line can monitor product quality in real-time, detecting defects early in the process. This reduces scrap rates and ensures that only high-quality products reach the customer.

Enhanced Safety: IIoT devices can monitor hazardous conditions, such as gas leaks or excessive temperatures, and trigger alerts or automated shutdowns to prevent accidents. This improves worker safety and reduces the risk of environmental damage.

Remote Monitoring and Control: IIoT enables manufacturers to monitor and control equipment and processes remotely, even from across the globe. This is particularly valuable for geographically dispersed operations or for equipment located in hazardous or inaccessible areas.

Inventory Management: IIoT sensors can track inventory levels in real-time, automating reordering processes and preventing stockouts or overstocking.

Energy Efficiency: By monitoring energy consumption and identifying areas of waste, IIoT solutions can help manufacturers reduce their energy costs and their environmental footprint.

BENCOR’s Role in the IIoT Revolution

BENCOR is at the forefront of providing the PCB design, fabrication, and assembly services that are essential for the IIoT revolution. With over 30 years of experience, BENCOR has the expertise to deliver high-quality, reliable PCBs that meet the demanding requirements of industrial applications. Here’s how BENCOR supports IIoT:

- Design Expertise: BENCOR’s engineers have extensive experience in designing PCBs for IIoT applications, including high-speed digital design, controlled impedance, and RF/wireless design. They can work with clients to select the appropriate sensors, communication protocols, and processing units for their specific needs.

- Advanced Manufacturing Capabilities: BENCOR utilizes state-of-the-art equipment and processes to manufacture PCBs that meet the highest quality standards. This includes capabilities for multi-layer boards, fine-pitch components, and advanced materials.

- Rigorous Testing: BENCOR performs thorough testing and inspection to ensure that PCBs meet the required specifications and will perform reliably in the field.

- Turnkey Solutions: BENCOR offers a complete range of services, from design and prototyping to full-scale production and assembly. This “one-stop-shop” approach simplifies the process for clients and ensures seamless integration of the PCB into their IIoT devices.

- Domestic and off-shore procurement: BENCOR provides domestic and off-shore PCB procurement services to ensure you receive exactly what you are looking for at the lowest price available.

The Future of IIoT and Smart PCBs

The IIoT is still in its early stages of adoption, but its growth is accelerating rapidly. As technology continues to advance, we can expect to see even more sophisticated smart PCBs with greater processing power, enhanced connectivity, and integrated artificial intelligence (AI) capabilities. These advancements will further optimize manufacturing processes, create new business models, and drive unprecedented levels of efficiency and productivity.

BENCOR is committed to staying at the cutting edge of PCB technology and to providing its customers with the solutions they need to succeed in the age of the IIoT. If you’re looking for a reliable partner to help you develop and manufacture smart PCBs for your IIoT applications, contact BENCOR today. We’re ready to help you transform your operations and unlock the full potential of the Industrial Internet of Things. Our team are always ready to answer any questions.