In the journey of creating an electronic product, the successful design and assembly of the Printed Circuit Board (PCB) is a monumental achievement. It’s the brain, the central nervous system of the device. However, a PCB on its own is rarely the final product. The critical, final stage of manufacturing is transforming that populated board, along with a host of other components, into a fully functional, enclosed, and market-ready system. This complex process is known in the industry as box build assembly, or systems integration. It’s the crucial step where individual components become a cohesive whole, ready for the end-user. Optimizing this process is paramount, as inefficiencies or errors at this final stage can lead to costly delays, quality issues, and logistical nightmares. As a proud American manufacturer with decades of experience, BENCOR offers comprehensive box build services, providing a seamless path from individual components to a complete, expertly assembled system right here in our Texas facility.

What is a Box Build Assembly? Defining the Comprehensive Scope

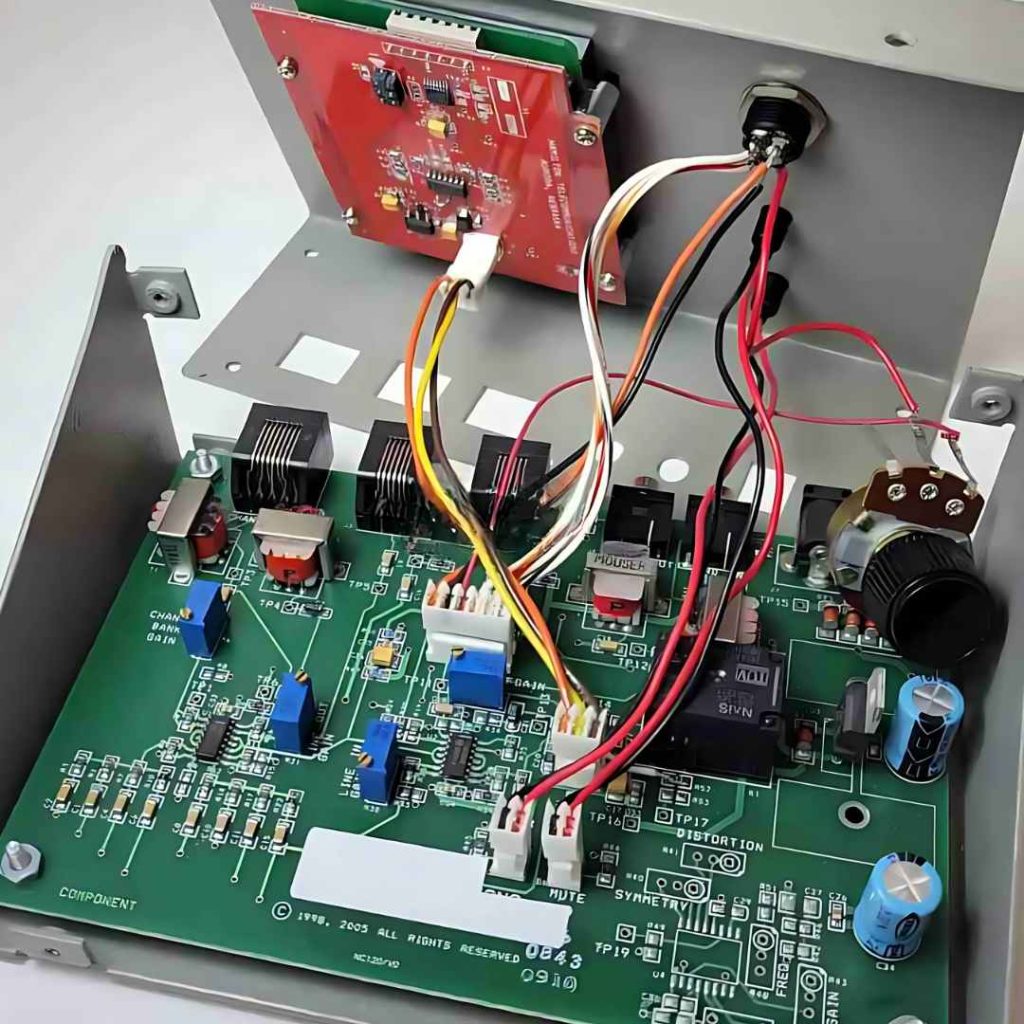

“Box build assembly” is a broad term that encompasses a wide spectrum of services, ranging from the very simple to the incredibly complex. At its most basic, a box build might involve placing a single PCB assembly into a small enclosure, connecting a power supply, and installing a few connectors. At the other end of the spectrum, it could involve assembling a large, multi-rack system complete with dozens of PCBs, intricate wire harnesses, power supplies, cooling systems, displays, and custom-fabricated mechanical components.

Common Elements of a Box Build

A comprehensive box build service can include a multitude of tasks, tailored to the specific product:

- System-Level Assembly: The core task of installing all necessary sub-assemblies (like a main PCB with several daughter cards) and individual components into the main chassis or enclosure.

- Enclosure Fabrication and Modification: Utilizing either off-the-shelf enclosures that may require modification (e.g., drilling holes, adding brackets) or integrating fully custom-fabricated enclosures, perhaps created through processes like sheet metal fabrication or injection molding.

- Installation of PCBs: Securely mounting all Printed Circuit Board Assemblies, ensuring proper alignment, standoffs, and connections.

- Cable and Wire Harness Installation: Meticulously routing and connecting custom cable assemblies and wire harnesses between the PCBs, power supplies, user interfaces, and external connectors.

- Installation of Additional Components: Integrating all other parts that make up the system, such as power supplies, cooling fans, fuses, switches, buttons, displays, and internal storage devices.

- Software Loading and Configuration: Installing firmware or operating system software onto the main processor and configuring the device to its required settings.

- Final Product Testing: Performing comprehensive functional tests on the fully assembled unit to ensure every aspect of the product works as intended.

- Packaging and Labeling: Custom packaging, adding serial numbers, barcodes, branding, and preparing the final product for shipment directly to the end customer or distribution center.

Key Benefits of Partnering with a CEM for Box Build Services

For many companies, attempting to manage complex box build assembly in-house can be a significant drain on resources. Partnering with a capable Contract Electronics Manufacturer (CEM) like BENCOR for these final integration services offers substantial strategic advantages.

Streamlined Supply Chain and Logistics

Perhaps the greatest benefit is the radical simplification of your supply chain. Instead of managing separate vendors for PCB assembly, cable manufacturing, mechanical components, and final assembly, you entrust everything to a single, accountable partner. This drastically reduces the complexity of vendor management, procurement, and inventory control.

Reduced Costs and Improved Efficiency

A dedicated CEM benefits from economies of scale and has established, optimized processes for system integration. This translates to greater efficiency and lower overall costs compared to setting up and staffing an in-house assembly line. It eliminates your overhead costs for additional factory space, specialized tools, and skilled assembly labor.

Accelerated Time-to-Market

An experienced box build partner can often work on different aspects of the project in parallel. For example, sub-assemblies can be built while custom enclosures or other long-lead-time components are being procured. Furthermore, experienced technicians who assemble similar systems daily work with greater speed and fewer errors, preventing the kinds of mistakes that can cause significant delays in the final stages of production.

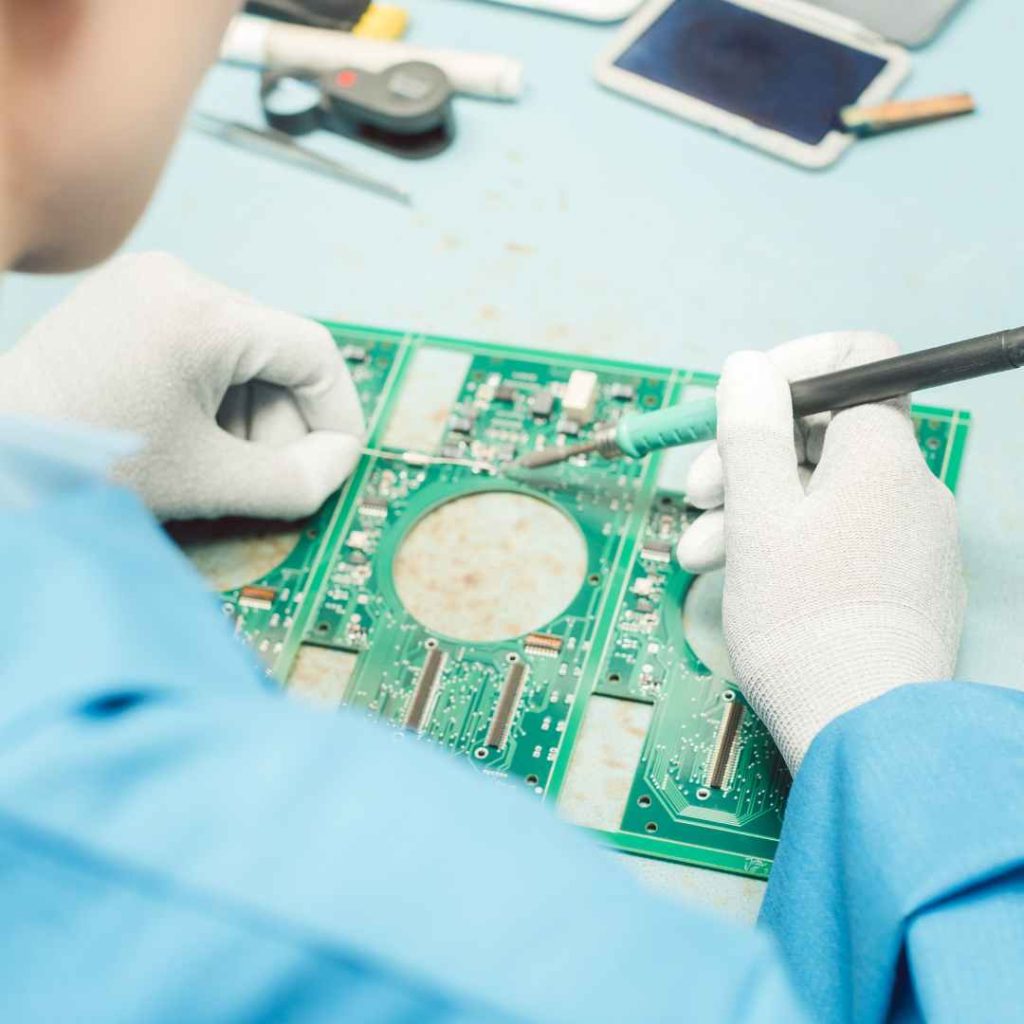

Enhanced Quality and Product Reliability

A quality-focused CEM will have documented work instructions, robust quality checkpoints, and dedicated testing procedures specifically for system-level assembly. Their technicians possess expertise in critical areas like applying correct torque specifications for mechanical fasteners, proper cable routing techniques to avoid signal interference, and executing comprehensive final system tests, all of which contribute to a more reliable and professional final product.

Critical Considerations for an Optimized Box Build Process

To ensure a smooth and successful box build, collaboration and meticulous planning are key. The quality of the final product is directly dependent on the quality of the information provided to the assembly partner.

Detailed and Accurate Documentation is Paramount

- Complete Bill of Materials (BOM): The BOM for a box build must extend beyond just the electronic components on the PCB. It needs to include every single part: every screw, washer, bracket, cable tie, label, wire, connector, and piece of mechanical hardware required for the final assembly.

- Detailed Assembly Drawings: Clear, unambiguous drawings are essential. 3D CAD models are often preferred as they can show the precise placement and orientation of every sub-assembly and component. Detailed 2D drawings should also be provided to specify critical dimensions and tolerances.

- Schematics and Wiring Diagrams: Complete electrical schematics and point-to-point wire run lists are necessary for the technicians to correctly install and connect all cable and wire harnesses.

- Clear Work Instructions: While an experienced CEM can develop their own internal instructions, providing a clear, step-by-step guide from your engineering team can prevent ambiguity and ensure the assembly sequence matches the design intent.

- Comprehensive Test Procedures: A detailed, documented plan for final product testing is non-negotiable. It should specify the tests to be performed, the equipment required, and the expected pass/fail criteria.

Thoughtful Enclosure and System Design

The physical design of the enclosure should follow Design for Assembly (DFA) principles, making it as easy as possible to access and install components. Considerations for thermal management, such as airflow paths and fan placements, must be integrated into the design. Accessibility for testing probes and for potential future servicing should also be planned for.

Meticulous Cable and Harness Management

Cable routing is both an art and a science. Properly designed cable assemblies with precise lengths, correct connector orientations, and effective strain relief are crucial. Within the box, cables must be routed to avoid obstructing airflow, creating electromagnetic interference (EMI/RFI) with sensitive circuits, or being pinched by mechanical parts. Clear labeling of all cables is essential for a clean and serviceable build.

A Robust and Tiered Testing Strategy

The most effective testing strategy involves multiple stages. Ideally, sub-assemblies like the main PCB are tested individually before being integrated into the final system. After full assembly, a comprehensive Final Functional Test (FCT) is performed to verify all features of the product. For high-reliability applications, burn-in testing (running the device under load for an extended period) can help identify any early component failures. Finally, electrical safety tests like Hi-Pot (high potential) and ground bond testing may be required.

The BENCOR Advantage: Your American Partner for System Integration

At BENCOR, our expertise extends far beyond the circuit board. We pride ourselves on our ability to take our customers’ projects across the finish line with our comprehensive box build assembly services. Our vertically integrated capabilities, combining PCB assembly, custom cable manufacturing, and final system integration all under one roof in our Texas facility, provide a uniquely streamlined and powerful solution for our partners.

Entrusting the entire assembly of your product to a single, accountable American partner eliminates the logistical friction and potential for miscommunication that can occur when dealing with multiple vendors. It represents a commitment to end-to-end quality control, where the same standards of excellence are applied from the placement of the smallest SMT component to the final torque of a chassis screw. This is American craftsmanship in its truest form – seeing a complex project through from start to finish with pride and precision. Our dedicated project managers work closely with your team to ensure all documentation is clear, processes are optimized, and you are kept informed every step of the way.

Conclusion: Box build assembly is the critical final act in the manufacturing play, transforming a collection of carefully engineered components into a complete, functional product ready to perform its mission. Success in this stage hinges on clear documentation, thoughtful system design, and, most importantly, the selection of a capable and experienced manufacturing partner. By partnering with a CEM like BENCOR for complete box build services, companies can streamline their supply chain, reduce operational costs, accelerate their time-to-market, and ensure the final product is built to the highest quality standards. When you’re ready to move from components to a complete system, trust BENCOR to be the expert, US-based partner that brings your product to life.