In the hyper-competitive global marketplace of 2025, the race to innovate is more intense than ever. Speed is no longer just an advantage; it’s a fundamental requirement for survival and success. The ability to move a groundbreaking idea from a concept to a market-ready product faster than the competition can define leadership, capture market share, and establish a brand as a forward-thinking powerhouse. Within the complex product development lifecycle, the prototyping stage can often become a significant bottleneck, a waiting period that stalls momentum and delays crucial feedback. This is where quick-turn prototyping emerges as a powerful strategic tool. It’s a philosophy and a process designed to dramatically compress this critical phase, directly accelerating a company’s entire innovation cycle. As a proud and agile American manufacturer, BENCOR is dedicated to providing the rapid, reliable quick-turn prototyping services that empower our nation’s innovators to design, test, and iterate at the speed of inspiration.

The Innovation Cycle: A Race Against Time

At its core, electronic product development follows an iterative loop. It begins with an idea, which is translated into a schematic and a PCB layout design. This design must then be physically realized as a prototype. The prototype is then rigorously tested and validated. Based on the results, the design is refined, and the cycle begins anew. This Design-Build-Test-Refine loop may be repeated several times until the product meets all its performance, quality, and cost targets.

The total time-to-market for a new product is largely determined by the duration and number of these iterative cycles. If each turn of the cycle—specifically the “Build” phase of getting a physical prototype in hand—takes several weeks, the entire project timeline stretches out, momentum wanes, and the window of market opportunity can begin to close.

The critical bottleneck is the time between finalizing a design iteration and having a functional board on the test bench. The faster an engineering team can complete this loop, the more iterations they can perform within a given timeframe. More iterations lead to more refinement, more bug fixes, better feature implementation, and ultimately, a more robust and successful final product. Quick-turn prototyping directly attacks this bottleneck, transforming it from a roadblock into an accelerator.

How Quick-Turn Prototyping Acts as an Innovation Accelerator

By drastically reducing the time it takes to get from a digital design file to a physical, testable prototype, quick-turn services fundamentally change the dynamics of product development and provide a significant competitive edge.

Enabling Rapid Iteration and “Failing Faster”

- Consider a project with a three-month window for design validation. If each prototype turn takes four weeks, the team might only manage two, perhaps three, iterations. They are forced to be extremely conservative with changes. However, if a quick-turn service can deliver those same prototypes in a matter of days, that same team can now cycle through five, seven, or even more iterations.

- This speed enables the powerful concept of “failing faster.” It gives engineers the freedom to test more ambitious ideas and bold design changes, knowing that if an approach doesn’t work, they haven’t lost a month of valuable time. They can quickly discard unworkable concepts and pivot to more promising solutions, dramatically increasing the efficiency of the innovation process.

Compressing the Design-Build-Test Loop

- When prototype lead times are long, engineers are often forced to switch context to other projects while they wait. When the boards finally arrive weeks later, they must spend valuable time re-familiarizing themselves with the design’s nuances. Quick-turn prototyping keeps the project top-of-mind. A design finalized on Monday can lead to a board being tested by the following week, allowing the engineering team to maintain focus, context, and momentum, which leads to more efficient and insightful problem-solving.

Gaining a Critical Competitive Edge

- In many technology sectors, being first to market with a new product or a key feature can be the deciding factor in its success. It allows a company to capture initial market share, establish itself as an industry leader, and often command premium pricing. Quick-turn prototyping is a direct strategic tool for achieving this speed advantage. It also allows a company to be more agile, enabling them to quickly react to customer feedback from an initial release or respond to a competitor’s move with a rapid product update.

Building Confidence for Stakeholders and Investors

- For startups seeking funding or internal teams justifying project budgets, demonstrating progress is key. Quickly turning a set of design files into a tangible, working prototype is a powerful way to show momentum and execution capability. It proves the concept is viable and builds immense confidence among investors, executives, and other stakeholders, helping to secure the resources needed to see the project through to completion.

What Enables a True Quick-Turn Prototyping Service?

Promising speed is easy; delivering it consistently while maintaining quality is hard. A genuine quick-turn capability is not just about rushing; it requires a specific infrastructure, optimized processes, and a company culture built around agility.

- Streamlined Quoting and Ordering: The process must begin with speed. This involves having dedicated staff and potentially online tools to generate accurate quotes and process orders in hours, not days.

- Agile Front-End Engineering: An experienced CAM and DFM (Design for Manufacturability) engineering team is crucial. They must be able to quickly analyze incoming design files, identify any potential showstoppers or manufacturing issues, and communicate clearly and rapidly with the customer to resolve them before fabrication begins.

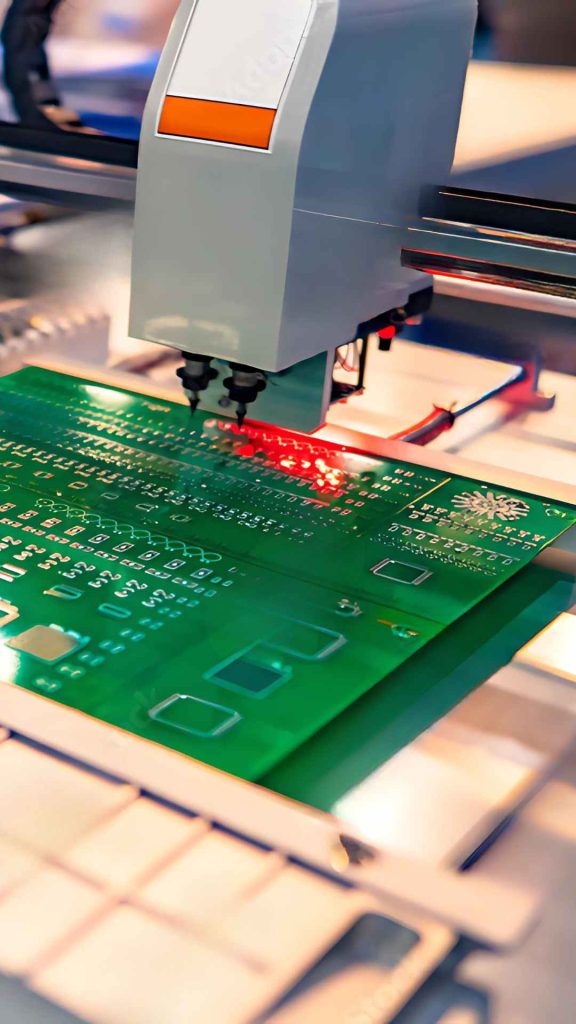

- Flexible Manufacturing and Dedicated Lines: The manufacturer must have the flexibility in their production scheduling to prioritize prototype runs without disrupting larger, ongoing production orders. Many leading CEMs maintain dedicated NPI (New Product Introduction) or prototyping lines specifically for this purpose.

- Robust Supply Chain for Components: Waiting for parts is a common bottleneck. A top-tier quick-turn provider has strong relationships with major component distributors to quickly source parts for low-volume builds. They often maintain an in-house inventory of common resistors, capacitors, and other passive components to further speed up the process.

Efficient Communication: Clear, constant, and rapid communication is the lifeblood of a quick-turn project. Having a single, responsive point of contact who can answer questions and keep the project moving forward is essential.

The BENCOR Advantage: Speed and Quality, Made in the USA

At BENCOR, we are passionately committed to fueling American innovation. We understand that for our partners across the United States, speed is a critical component of success, and our quick-turn prototyping services are structured to provide that crucial advantage. We deliver more than just fast boards; we deliver reliable, high-quality prototypes that empower our customers to lead their fields.

The Domestic Advantage for Speed

- Our location here in Brenham, Texas, provides an inherent and massive advantage for quick-turn prototyping.

- No International Shipping Delays: By choosing BENCOR, you eliminate the weeks of uncertainty and transit time associated with overseas shipping and customs clearance. What takes weeks from across the ocean can take mere days from our facility to yours.

- Seamless, Real-Time Communication: Our team operates on your time. When questions or design clarifications arise, we can resolve them immediately during normal US business hours via a simple phone call or email, preventing the multi-day delays that time zone differences can cause.

- Unwavering IP Security: Prototyping often involves a company’s most sensitive and valuable new intellectual property. Partnering with a trusted US-based manufacturer provides the highest level of confidence and legal protection for your designs.

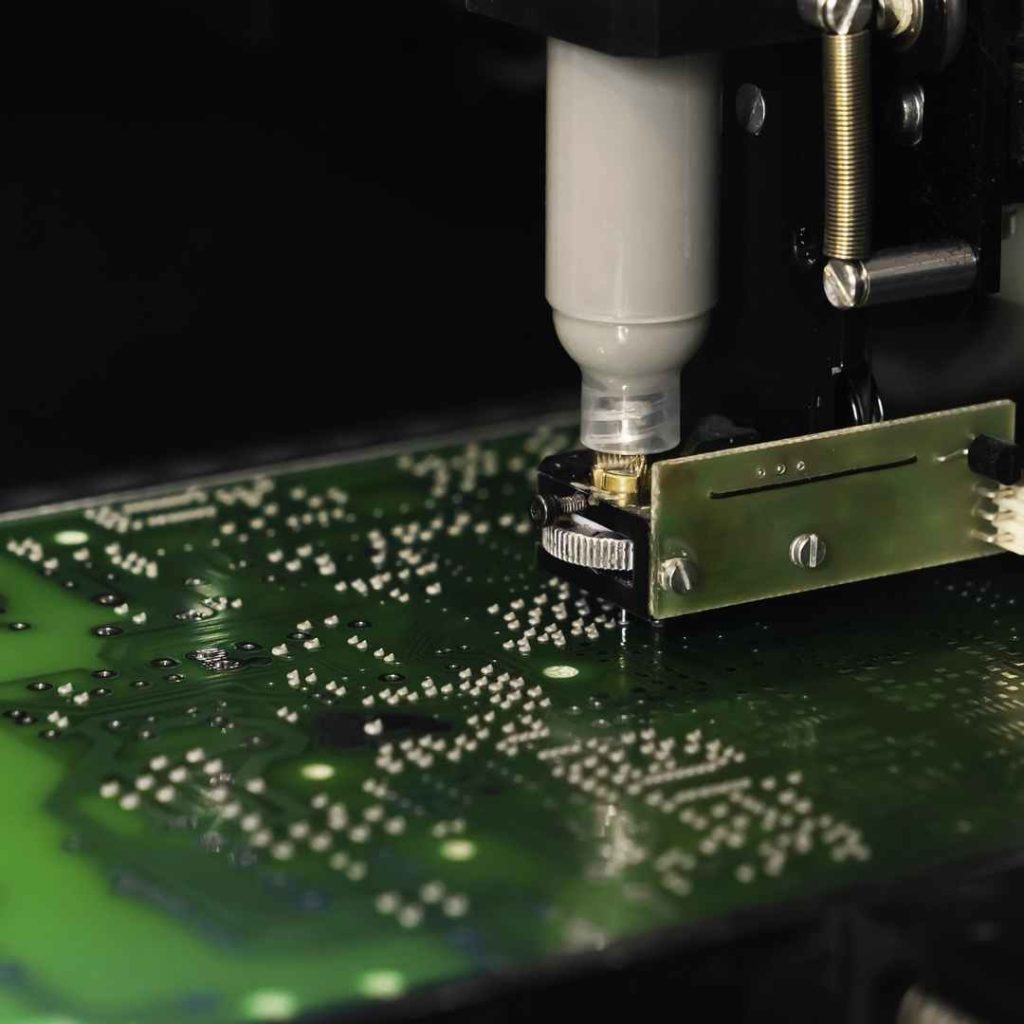

Quality is Never Sacrificed for Speed

A fast prototype that is unreliable or built incorrectly is worse than useless; it’s misleading and can derail a project. At BENCOR, we believe that speed and quality must go hand-in-hand. Our quick-turn prototyping process adheres to the same rigorous quality standards and process controls, governed by our ISO 9001:2015 certification, that we apply to our high-volume production runs. Our goal is to deliver a reliable prototype, fast, so you can trust your test results and make informed design decisions.

Experience that Accelerates

With our legacy of manufacturing excellence dating back to 1992, BENCOR’s team brings decades of American expertise to every project. This deep experience allows us to quickly anticipate potential manufacturing issues, provide fast and accurate DFM feedback that can save you from a costly respin, and navigate the assembly process with an efficiency that only comes from years of practice. This is the tangible value of experienced American craftsmanship applied to accelerating your innovation.

Conclusion: In the modern race to market, the speed of your innovation cycle is your primary competitive weapon. Quick-turn prototyping is the engine that powers this acceleration, enabling the rapid iteration, fast failure, and continuous refinement needed to create superior products. By compressing the design-build-test loop, companies can innovate more effectively and seize market opportunities. BENCOR is proud to be the ideal domestic partner for this mission, offering the perfect synthesis of speed, uncompromising quality, deep expertise, and the inherent logistical and security advantages of being a US-based manufacturer. Let us help you accelerate your next breakthrough and win in the marketplace.