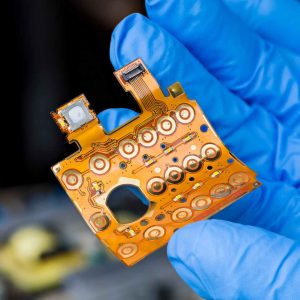

For years, the conversation around sustainability in electronics manufacturing has focused heavily on materials—removing lead from solder, eliminating hazardous substances (RoHS), and recycling e-waste. While these are critical steps, there is a massive, invisible contributor to a product’s carbon footprint that is often overlooked: logistics. The physical distance a product travels from the factory floor to the end-user has a profound environmental impact. In a globalized economy where a circuit board might cross the Pacific Ocean multiple times before it reaches a customer, the carbon cost of transportation is staggering. However, a shift is underway. As companies look to decarbonize their operations, they are realizing that “Made in USA” is one of the most effective sustainability strategies available. Partnering with a domestic manufacturer like BENCOR does more than secure your supply chain; it dramatically shortens your logistics loop, slashing emissions and creating a leaner, greener, and more responsible business model.

The Hidden Carbon Cost of Offshore Manufacturing

To understand the green advantage of domestic manufacturing, we must first look at the environmental reality of the alternative. The traditional model of outsourcing to Asia relies on a massive, fuel-hungry global logistics network to bridge the gap between production and consumption.

The Emissions of Maritime and Air Transport

The backbone of global trade is the container ship. While efficient in terms of volume, the maritime shipping industry is a major source of greenhouse gases, burning low-grade “bunker fuel” that emits high levels of sulfur and nitrogen oxides. A single PCB assembly manufactured overseas must traverse thousands of nautical miles to reach a US port, followed by intermodal transport to a distribution center.

The situation becomes exponentially worse when supply chain disruptions occur. When ocean freight is delayed, companies often resort to air freight to meet deadlines. Shipping heavy electronic assemblies by air releases significantly more CO2 per ton-mile than ocean transport. By relying on distant suppliers, companies are constantly one delay away from having to make a choice that is disastrous for their carbon footprint.

The Waste of Over-Production and Obsolescence

Long supply chains impose a rigid and unforgiving timeline on manufacturers, often forcing them to operate with lead times measured in quarters rather than weeks. To insulate themselves against the unpredictability of ocean transit and potential delays, businesses are compelled to over-order significantly, creating massive buffers of “safety stock” just to ensure continuity. This precautionary bloating of inventory has a tangible physical and environmental cost. It necessitates expansive, climate-controlled warehousing space that consumes electricity 24/7 to maintain strict temperature and humidity levels, essentially burning energy to store products that are sitting idle.

Furthermore, this lack of agility creates a high risk of obsolescence, particularly in the fast-paced electronics sector where revisions happen frequently. When an engineering change order (ECO) is issued or a design is improved, a company relying on a long-range supply chain may still have thousands of units of the old revision sitting in a container halfway across the Pacific or stacked in a warehouse. These units often become instant electronic waste, condemned to be scrapped before they are ever used. This represents a profound waste of raw materials, manufacturing labor, and the embedded carbon used to produce them, highlighting the inherent inefficiency and environmental irresponsibility of a disconnected, long-range supply chain.

The Domestic Advantage: Decarbonizing through Proximity

Choosing a US-based partner like BENCOR fundamentally alters this equation. By bringing manufacturing closer to the point of consumption, you eliminate the massive carbon overhead of transoceanic shipping.

From Oceans to Highways: Drastically Reducing Miles

When you manufacture with BENCOR in Texas, your logistics loop shrinks from thousands of miles to hundreds. Finished goods can be shipped via ground transport—truck or rail—to anywhere in the North American market in a matter of days. This drastic reduction in transportation miles yields an immediate and measurable drop in Scope 3 greenhouse gas emissions (emissions from assets not owned or controlled by the reporting organization). For companies with ambitious Net Zero goals, reshoring manufacturing is often the “low-hanging fruit” for making a significant impact.

The Efficiency of "Just-in-Time" Manufacturing

Proximity enables agility. Because BENCOR operates in the same time zones and geographic region as our customers, we can implement true Just-in-Time (JIT) manufacturing strategies. Instead of ordering months in advance and hoarding inventory, our customers can align production closely with actual demand. This lean approach minimizes waste, reduces the energy footprint of warehousing, and virtually eliminates the scrapping of obsolete inventory caused by long lead times. We build what you need, when you need it, ensuring that every kilowatt-hour of energy used in production creates value, not waste.

BENCOR: Your Partner in Sustainable Growth

At BENCOR, we view sustainability as an extension of efficiency and quality. A well-run factory that minimizes scrap, optimizes logistics, and operates responsibly is inherently a green factory.

We are committed to helping our customers achieve their environmental goals. By offering a centralized manufacturing hub in Texas, we provide a logistical sweet spot for distributing products across North America. Our focus on quality and “doing it right the first time” prevents the environmental waste associated with rework and returns. We believe that American industry has a responsibility to lead the way in sustainable practices, proving that economic growth and environmental stewardship are not mutually exclusive.

Conclusion

In 2025, sustainability is no longer a “nice-to-have” marketing slogan; it is a core business requirement demanded by consumers, investors, and regulators. While material selection and recycling are important, they are only part of the story. The most impactful decision a company can make to lower its carbon footprint is to shorten its supply chain. By bringing production home to the US and partnering with a domestic leader like BENCOR, companies can slash transportation emissions, eliminate inventory waste, and leverage a cleaner, more regulated manufacturing environment. “Made in USA” is more than a label of quality; it is a badge of sustainability. Let’s build a greener future together, by building it here.