When we think of a modern commercial kitchen—whether it’s the fast-paced environment of a global quick-service restaurant or the bustling heart of a fine-dining establishment—we often picture stainless steel, open flames, and intense culinary activity. What may not immediately come to mind is the sophisticated network of high-technology electronics that underpins its entire operation. Today’s kitchens are powered by smart ovens with programmable cooking cycles, intelligent deep fryers that regulate temperature and oil life, digital point-of-sale (POS) systems, automated beverage dispensers, and complex kitchen display systems (KDS) that manage order flow. This infusion of technology has revolutionized efficiency, consistency, and safety in the food service industry. However, it has also created a formidable engineering challenge: designing Printed Circuit Board (PCB) assemblies that can not only survive, but thrive, in one of the most hostile environments imaginable. As a dedicated American manufacturer with deep experience in building rugged industrial electronics, BENCOR understands the unique demands of this environment and is proud to build the reliable assemblies that power our nation’s vibrant food service industry.

The Commercial Kitchen: A Uniquely Hostile Environment for Electronics

A commercial kitchen is a relentless gauntlet of environmental threats that are often far more severe than those faced by typical consumer or office electronics. Designing a PCB for this setting requires a deep appreciation for the specific hazards it will encounter daily.

Extreme Temperature Swings and Sustained High Heat

The most obvious threat is heat. PCBs in kitchen equipment are often in close proximity to ovens, grills, and deep fryers, subjecting them to high ambient temperatures. Beyond just sustained heat, they experience rapid and repeated thermal cycling as equipment is powered on for peak service hours and then cooled down. This cycling induces mechanical stress on solder joints, components, and the PCB laminate itself, accelerating fatigue and potential failure.

Pervasive Moisture, Steam, and Aerosolized Grease

The air in a commercial kitchen is laden with moisture and steam from cooking, boiling, and constant washing. During nightly clean-up, equipment is often subjected to high-pressure water spray-downs. Compounding this is the presence of aerosolized grease from fryers, which can settle on surfaces and form a sticky, conductive, and corrosive film. This combination of moisture and contaminants is a recipe for short circuits, corrosion, and the degradation of electronic components.

Shock, Vibration, and Heavy Use

Kitchen equipment is built for utility, not delicate handling. Doors are slammed, carts are bumped into machines, and the constant operation of motors, compressors, and ventilation fans creates a background of persistent vibration. Electronic assemblies within this equipment must be mechanically robust enough to withstand these daily shocks and vibrations without solder joint failure or component detachment.

Frequent Chemical Exposure

To meet stringent health and safety standards, commercial kitchens are cleaned daily with powerful, industrial-grade cleaning agents, degreasers, and sanitizers. These harsh chemicals can be highly corrosive and can quickly degrade plastic enclosures, seals, cable jackets, and even the protective coatings on PCBs if the right materials are not chosen.

A Noisy Electrical Environment

The simultaneous operation of high-power equipment like induction cooktops, large mixers, and refrigeration compressors creates a significant amount of electromagnetic interference (EMI) and electrical noise on the power lines. Sensitive control circuits on a PCB must be properly designed and shielded to filter out this noise and prevent erratic behavior or malfunction.

Design and Manufacturing Strategies for Kitchen-Ready PCBs

To counter these threats, engineers and manufacturers must employ a suite of specific design and assembly strategies aimed at creating truly ruggedized electronic assemblies.

Robust Component Selection is the First Line of Defense

The process begins with choosing components that are up to the task. This means specifying industrial-grade or even automotive-grade parts that have a wider operating temperature range (e.g., -40°C to +105°C or +125°C). For user interfaces, sealed components like waterproof switches, buttons, and rotary encoders are essential to prevent the ingress of moisture and grease. Connectors should be chosen for their mechanical durability and, where necessary, should be of a sealed, IP-rated design.

Conformal Coating and Potting: The Ultimate Environmental Shield

This is arguably the most critical step in protecting the PCB itself. Conformal coating— a thin, protective polymeric film applied over the entire assembly—is essential. It creates a barrier that seals the board from moisture, humidity, grease, and cleaning chemicals, preventing corrosion and short circuits.

For the absolute highest level of protection, especially for boards in areas prone to direct spray or extreme vibration, potting or encapsulation is the solution. This process involves encasing the entire PCB assembly in a solid block of a durable material like epoxy or silicone. A potted assembly is rendered virtually impervious to its environment, providing maximum protection against moisture, shock, vibration, and chemicals.

Durable PCB Construction and Smart Layout

The design of the bare PCB itself plays a role. Using thicker copper (often 2oz or more, known as “heavy copper”) is common for traces carrying high currents to power heating elements or motors, as this helps manage heat and improves durability.

For connectors and other components that will experience significant mechanical stress, using through-hole (PTH) mounting provides a much stronger anchor to the board than standard surface-mount (SMT) pads. The layout must also incorporate best practices for EMC/EMI protection, such as proper grounding and filtering, to ensure the control circuits remain stable in an electrically noisy environment.

Assembly Techniques for Superior Mechanical Strength

Beyond standard assembly, ruggedization often requires extra steps. Large, heavy components like electrolytic capacitors or transformers can be prone to failing under vibration. Techniques like staking—applying a bead of specialized, high-strength adhesive (like an epoxy) to bond the side of the component to the PCB—can dramatically improve its vibration resistance.

The foundation of this mechanical strength, of course, is a perfectly formed solder joint, which results from a combination of excellent pad design and a meticulously controlled manufacturing process.

The Complete System: Thinking Beyond the Board

A rugged PCB is only as good as the enclosure that protects it. The final “box build” is critical.

Enclosures, Gaskets, and Seals

The final product enclosure must be designed to keep contaminants out. This involves using enclosures with appropriate IP (Ingress Protection) ratings, such as IP65 or higher, which signifies they are protected against dust and low-pressure water jets. Achieving this rating requires high-quality gaskets and seals on all seams, doors, and connector pass-throughs.

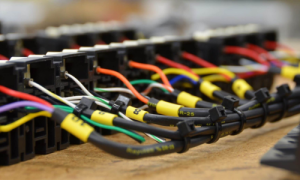

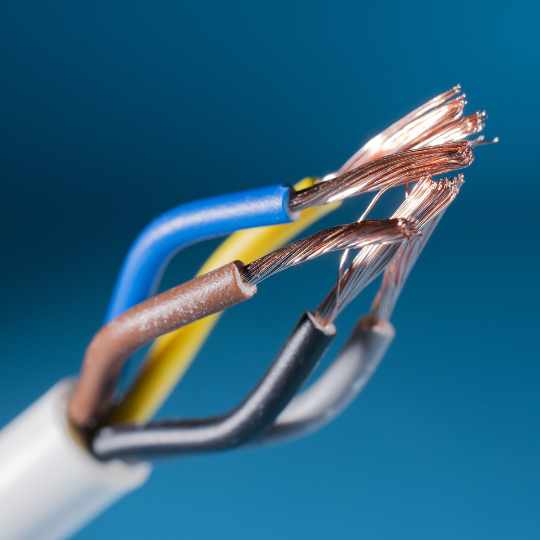

Cable and Connector Integrity

The cables and connectors that interface with the outside world are potential points of failure. Using rugged, sealed connectors and durable cable jackets that can resist heat, abrasion, and chemical exposure is essential. BENCOR’s expertise in custom cable assembly ensures these critical interconnects are built to the same high standards as the internal electronics.

BENCOR: Building for the Demands of the American Kitchen

At BENCOR, our extensive experience in serving a wide range of demanding industrial markets gives us a unique and powerful perspective on the challenges of creating rugged electronics. We understand what it takes to build a product that lasts. Our comprehensive suite of services—from high-quality PCB assembly and robust cable manufacturing to detailed box build integration—is perfectly suited to the needs of the food service equipment industry.

We believe that the high-paced, hard-working environment of the American commercial kitchen demands equipment of equal caliber. The reliability of this equipment is a direct reflection of the quality of the components inside. This is where our commitment to the high standards of American manufacturing shines. It’s a commitment to building things right, using the correct techniques like conformal coating and component staking, and applying rigorous quality control at every step. We take immense pride in building the reliable electronic “guts” that power these workhorse machines, helping to keep our nation’s restaurants, cafes, and kitchens running efficiently, day in and day out.

Conclusion:

The modern commercial kitchen is, without a doubt, one of the most challenging operating environments for any electronic device. Success in this market requires a holistic design and manufacturing approach that prioritizes ruggedness and reliability above all else. From the selection of industrial-grade components and the critical application of conformal coating or potting, to durable PCB construction and sealed enclosures, every detail matters. To bring such a product to life, you need a manufacturing partner who understands these unique demands. BENCOR is that expert American partner, with the proven processes, comprehensive services, and unwavering commitment to quality required to deliver the tough, reliable electronic assemblies that the fast food and restaurant industries depend on.